Vacuum Resistance Heating Furnaces

a widely used vacuum furnace

A laboratory vacuum resistance heating furnace is a specialized piece of equipment used in scientific and industrial settings for various heating and thermal treatment processes. They are among the most widely used vacuum furnaces. It operates on the principle of electrical resistance heating, where an electric current is passed through a resistive element, generating heat to achieve the desired temperature.

One of the main advantages of using a vacuum resistance heating furnace is the ability to create a controlled environment for heating processes. The furnace is designed to operate in a vacuum or controlled gas atmosphere, which allows for precise control over temperature, pressure, and atmosphere composition. This is particularly important when working with sensitive materials that require specific thermal conditions or when heat treatment processes need to be conducted in an inert or reducing environment.

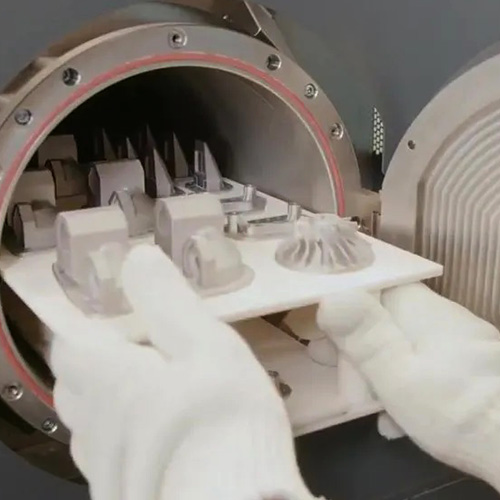

The most common applications of this furnace include the following: brazing, heat treatment, removal of wax and gas in investment casting, sintering of metals, alloys, and modern engineering ceramics, melting and refining metals, superalloys, powder metallurgy and related processes, single crystal growth, modern aerospace, chemical, ceramic industries, etc.

YARAN manufactures resistance furnaces under vacuum and with the ability to control the atmosphere and purge with neutral/oxidizing/reducing gas and the ability to quench the sample especially the working temperature of the furnaces which can be provided up to 2200 °C. The variety of applications of this category of vacuum furnaces has caused the variety of structures, service temperatures, and chamber shapes. For furnaces with a service temperature higher than 1000 °C, internal heating elements with heat shields are used, but in the temperature range lower than 1000 °C, furnaces with a retort structure (heating from the outside of the chamber) can also be used. YARAN produces furnaces up to 5 x 10-5 millibar vacuum, up to 2200 °C, and up to 3 liters in volume as standard, and systems outside of the company’s standard models can also be provided on request.

Features & Options

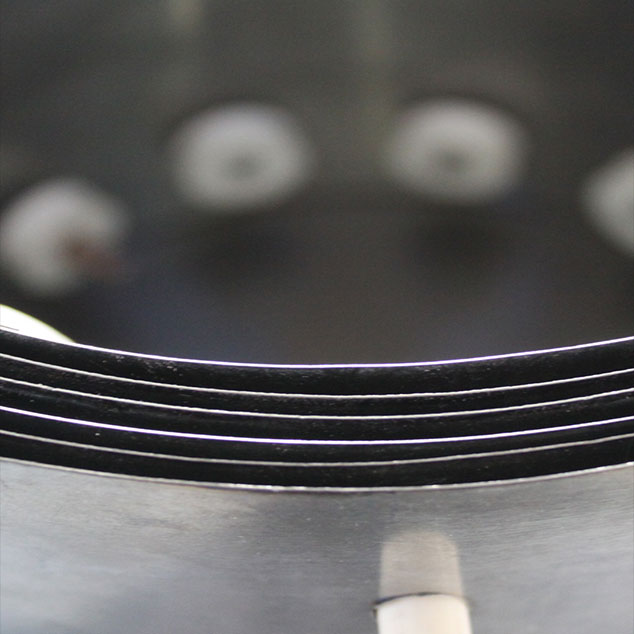

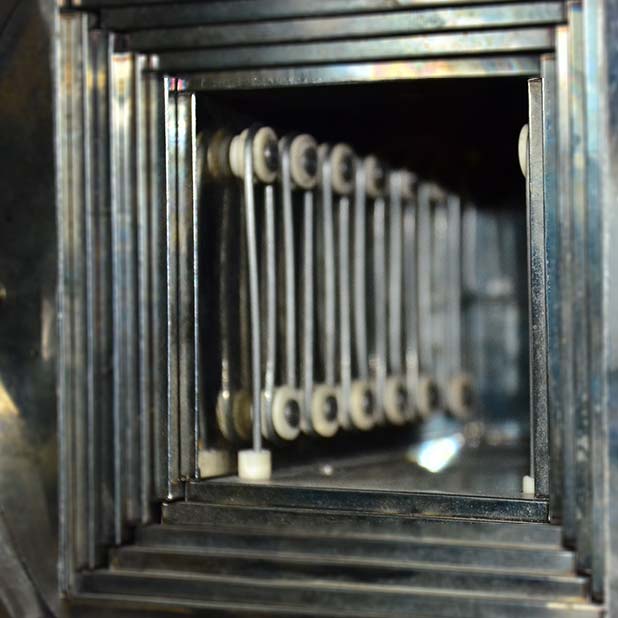

Mo/W Heating Chamber

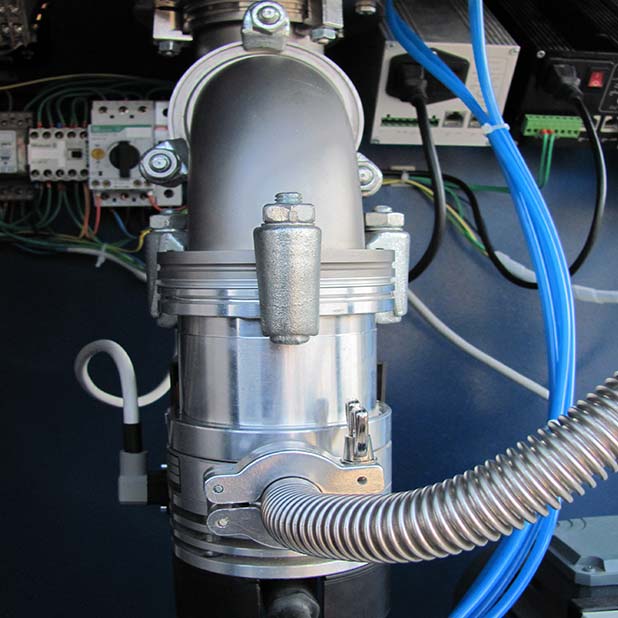

High Quality Vacuum Pump

Precise Instruments

Applications

Vacuum Sintering

Vacuum Heat Treathing