Retort Type Furnaces

A furnace with a controlled atmosphere and a wide variety of designs

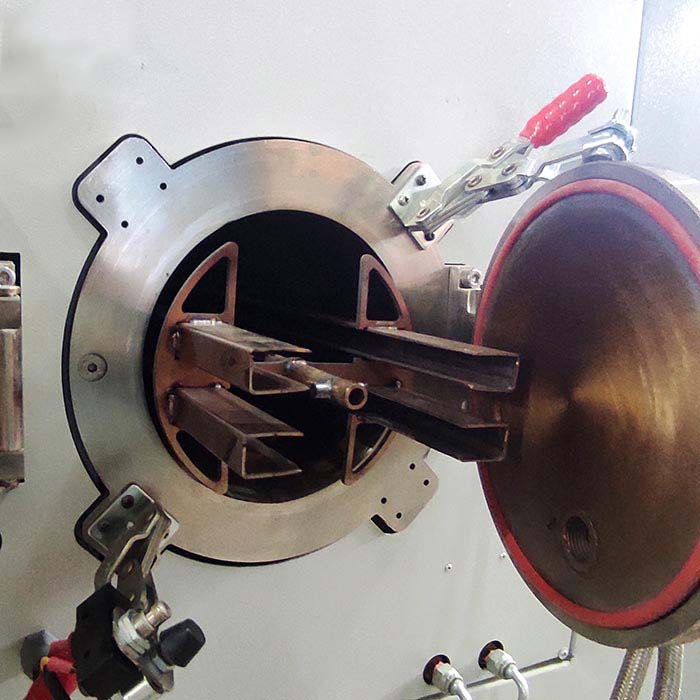

A retort-type furnace is a laboratory heating device commonly used for various applications such as heat treatment, annealing, sintering, and calcination of materials. It consists of a cylindrical chamber, known as the retort, which is designed to withstand high temperatures and maintain a controlled atmosphere during the heating process. The retort is typically made of high-temperature resistant materials such as quartz, ceramic, or stainless steel.

Retort furnaces are commonly used for heat treatment processes such as annealing, tempering, and hardening of metallic materials to enhance their mechanical properties. These furnaces are used for sintering ceramic powders to form solid, dense ceramic components with improved strength and durability. Retort-type furnaces are employed for calcination, roasting, or reduction of chemical compounds to produce desired chemical reactions or convert raw materials into final products. These furnaces are extensively used in laboratories for studying the behavior of materials at high temperatures, investigating phase transformations, and developing new materials with tailored properties.

YARAN manufactures different kinds of retort-type furnaces with different specifications. These furnaces use high-quality heating elements, such as resistance wires or heating coils, which are capable of reaching high temperatures quickly and efficiently. They are equipped with precise temperature control systems, allowing users to set and maintain specific temperature ranges. If a specific atmosphere is required for the process, gases can be introduced into the retort chamber through the gas inlet. The gas flow rate and composition can be adjusted to create an oxidizing, reducing, or inert atmosphere as needed. It is also possible to include a vacuum system to create a low-pressure environment inside the retort.