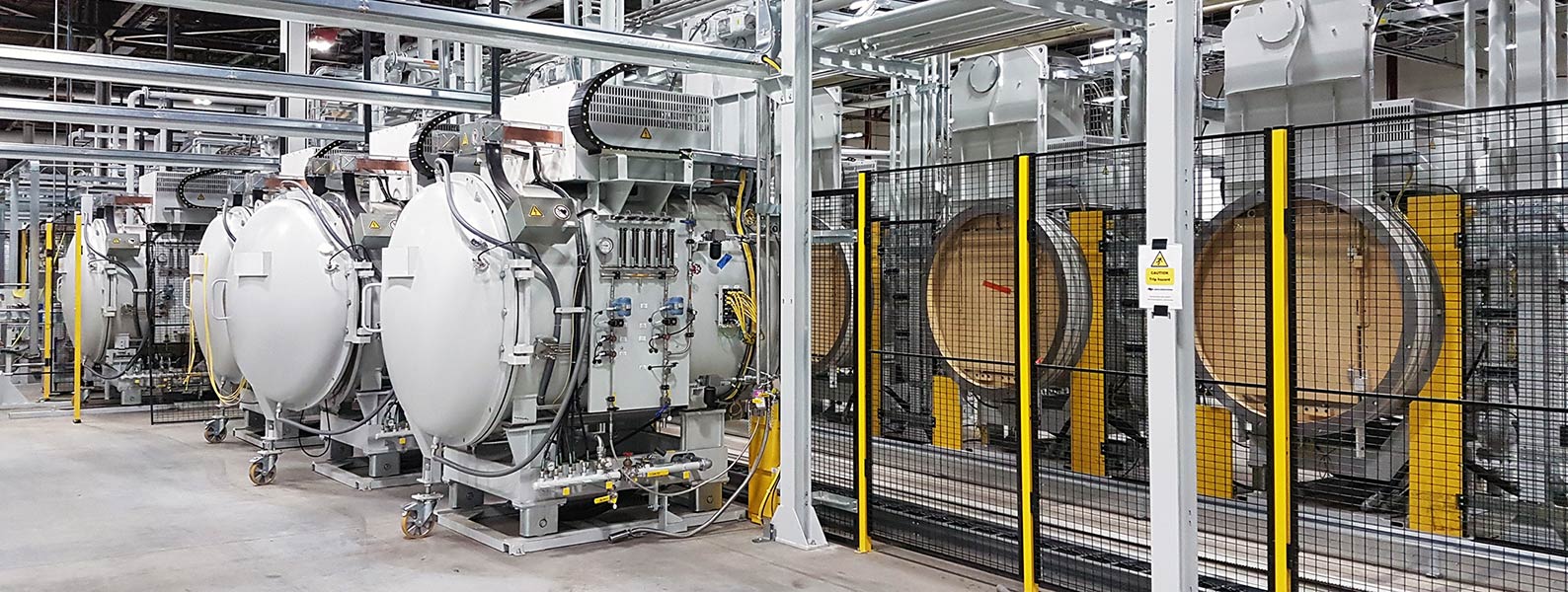

Carburizing Furnaces

Vacuum/low-pressure carburizing

These furnaces are made of modular installations dedicated to quenching, low-pressure/vacuum carburizing, and low-pressure carbonitriding. However, these flexible and scalable installations can integrate different processes within the same line.

These furnace control systems ensure that the parts are exposed to a precise concentration of carbon during the carburizing process. They are designed to provide uniform heating throughout the chamber. These are equipped with advanced control systems to monitor and regulate various parameters, such as temperature, gas flow rate, and carbon potential. This ensures precise control over the carburizing process, allowing for consistent results and minimizing the risk of defects.

Carburizing furnaces find applications in various industries. Carburizing is widely used in the automotive industry to manufacture components such as gears, shafts, and bearings. Carburizing furnaces play a crucial role in achieving the desired hardness and wear resistance required for these components to withstand the demanding conditions of automotive applications.

The aerospace industry also relies on carburizing furnaces for the production of critical components, such as landing gear parts and turbine engine components. Carburizing ensures the necessary strength and durability of these parts, contributing to the overall safety and reliability of aircraft.

Carburizing is commonly used in the production of heavy machinery components, such as gears for construction equipment and mining machinery. Carburizing furnaces enable the manufacturing of high-quality, long-lasting components that can withstand heavy loads and harsh operating conditions.

It is currently not possible to supply this product from ECM Group. Please call for more information.