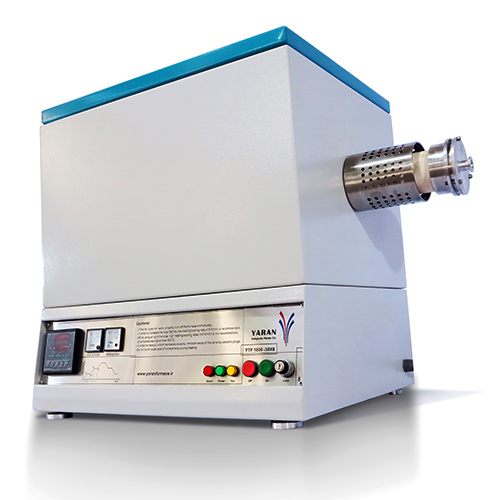

Tube Furnaces

A laboratory furnace with a controlled environment for the sample

A laboratory tube furnace is a versatile piece of equipment commonly used in scientific research and industrial applications. It is specifically designed for heating and thermal processing of materials in cylindrical or tubular forms, such as tubes, rods, wires, and small samples.

One of the distinguishing features of a laboratory tube furnace is its tubular shape, which allows for easy insertion and removal of samples. The furnace is equipped with a removable quartz or ceramic tube that acts as a protective barrier between the heating elements and the sample. This tube provides a controlled environment for the sample, preventing contamination and ensuring uniform heat distribution.

Similar to a muffle/box furnace, a laboratory tube furnace also includes a digital temperature controller to regulate the heating process. The temperature controller allows precise temperature control and can be programmed to follow specific heating profiles or ramp rates. Some advanced models may also have additional features like PID control, data logging, and remote monitoring capabilities.

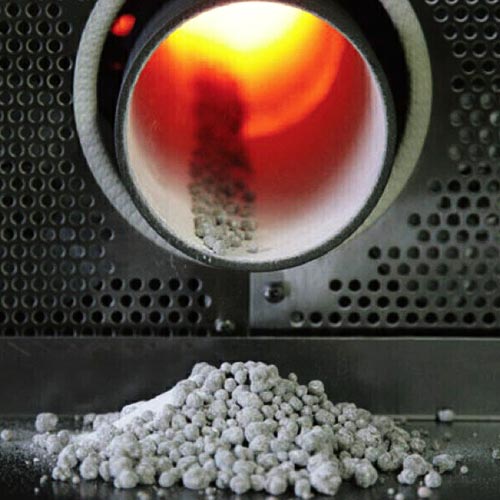

Laboratory tube furnaces find applications in various fields, including materials science, chemistry, geology, and engineering. They are commonly used for processes such as thermal decomposition, pyrolysis, crystallization, and synthesis of materials. Tube furnaces are particularly suitable for experiments involving controlled heating rates, rapid thermal processing, and high-temperature reactions.

YARAN designs and manufactures Laboratory tube furnaces from the maximum temperature of 1250 to 2300 ◦C as standard. Depending on the temperature range tubes can be made from different material like quartz (SiO2), stainless steel (310), alumina (Al2O3; 95%, 99%), graphite and silicon carbide (SiC). Heating is also dependent on temperature range and can be made of metal, silicon carbide, molybdenum disilicide and graphite. Temperature control in these furnaces is very precise.

Specifications

Nominal T(℃)

Heating Element

Tubes *

Zones

400 ~ 1250

Metallic

Q, S, A, C

1 ~ 4

1250 ~ 1450

SiC

A, C

1 ~ 2

1450 ~ 1800

MoSi2

A

1

1800 ~ 2300

Graphite

Graphite

1

* Q: Quartz (SiO2), S: Stainless Steel (310), A: Alumina (Al2O3; 95%, 99%), C: Silicon Carbide (SiC)

Features & Options

Atmosphere

Vacuum, Innert or Reducing

Split

Rotating Tube

Angled Tube