Vacuum Induction Heating Furnaces

an advanced furnace with a complex design

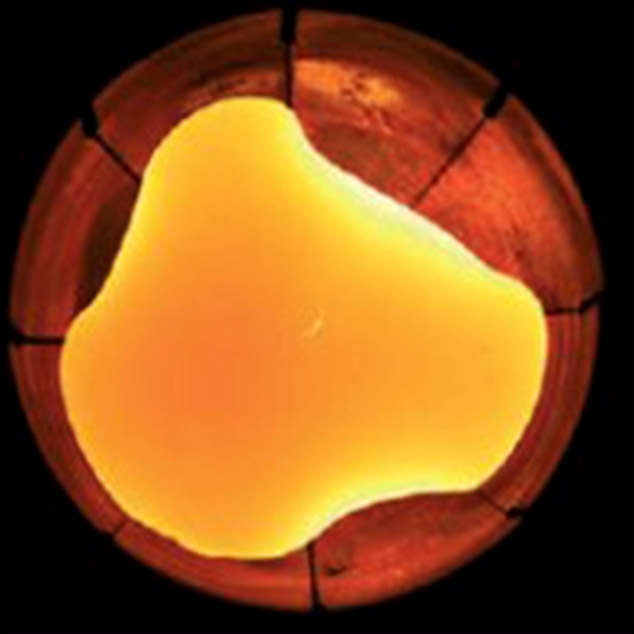

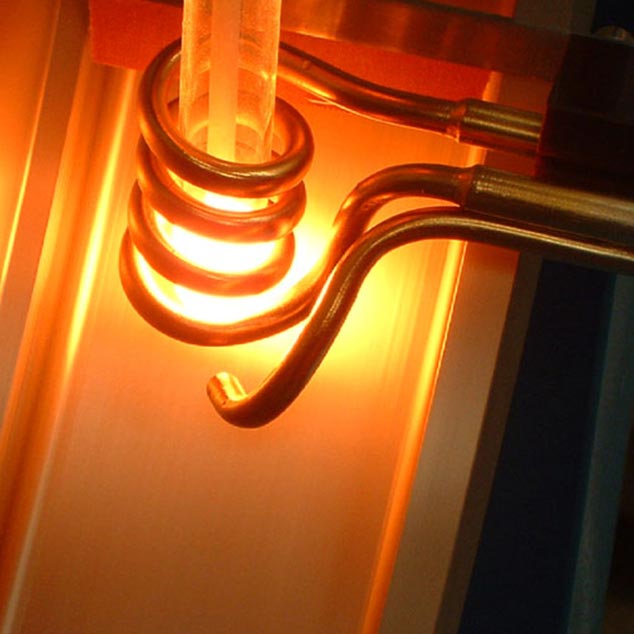

The induction method is a clean and useful method for heating metals. Vacuum Induction Melting (VIM) systems and in general Vacuum Induction Furnace (VIF) are one of the most widely used methods used in industries and advanced materials laboratories, which are used for alloying and producing precision casting parts. Heat treatment and brazing or hard soldering are also other uses of these furnaces. It utilizes the principle of induction heating, where an alternating magnetic field is generated by an induction coil, inducing an electric current in the material being heated.

One of the primary advantages of using a vacuum induction heating furnace is the ability to perform heat treatments under controlled atmospheric conditions. The furnace is designed to operate in a vacuum or controlled gas environment, which eliminates the presence of impurities and reduces oxidation and contamination during heating processes. This ensures high-quality and precise results, especially when working with sensitive or reactive materials.

All kinds of melting and casting, alloying in advanced material laboratories, the investment casting of super alloys (turbine parts such as blades and discs), melting of advanced alloys, degassing, heat treatment, and hard soldering are done with this method. Among the processes related to vacuum induction systems that are similar to the mentioned systems in terms of the main structure of the equipment are skull melting, melt levitation, and melt spinning.

YARAN is a manufacturer of vacuum Induction heating furnaces with the ability to control the atmosphere and the ability to melt and cast under vacuum and without leakage (vacuum failure or pressure rise). Device control, including temperature control (through induction frequency), pressure and vacuum control (through sensors and vacuum controller), control of inlet and outlet water flow rate and water temperature in the induction system and cold trap, control of gas entry and its flow rate, and … in these furnaces, it is done through PLC designed by the technical team of YARAN and all the data can be reported.

Features & Options

PLC Controlled

Accurate Induction Coil

HF Melting

Applications

Melting and Casting

Skull Milting

Melt Spinning