Vacuum Arc Melting Furnaces

A sophisticated furnace with special applications

A laboratory vacuum arc melting or remelting (VAM or VAR) furnace is a specialized piece of equipment used for the production of high-quality alloys, intermetallic compounds, and metallic glasses. It is commonly used in research and development laboratories, as well as in industries such as aerospace, automotive, and electronics.

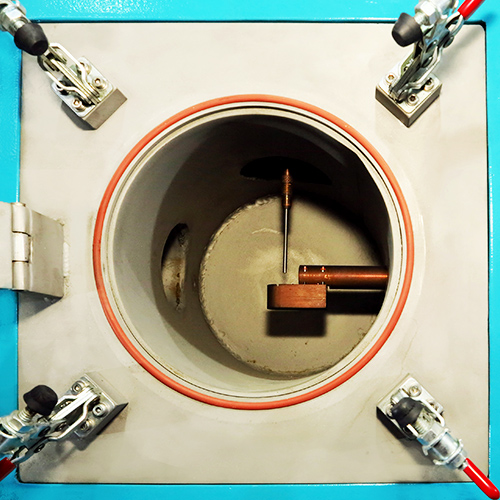

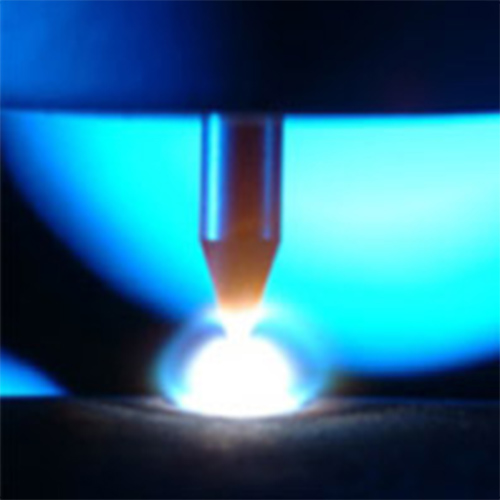

The vacuum arc melting process involves melting a metal or alloy sample in a vacuum environment using an electric arc. This method allows for precise control over the composition and purity of the final product, as well as the ability to produce materials with unique properties and microstructures.

One of the main advantages of using a vacuum arc melting furnace is the ability to achieve high-purity and homogenous melts. The furnace is designed to operate in a vacuum or controlled gas environment, which eliminates impurities and minimizes contamination during the melting process. This is particularly important when working with materials that are highly reactive or require precise control over their composition.

Laboratory vacuum arc melting furnaces find applications in various fields, including materials science, metallurgy, and alloy development. They are commonly used for melting and refining metals, alloys, and other materials with high melting points or specific composition requirements. These furnaces are particularly useful when working with materials that require a high level of purity, homogeneity, and control over their composition.

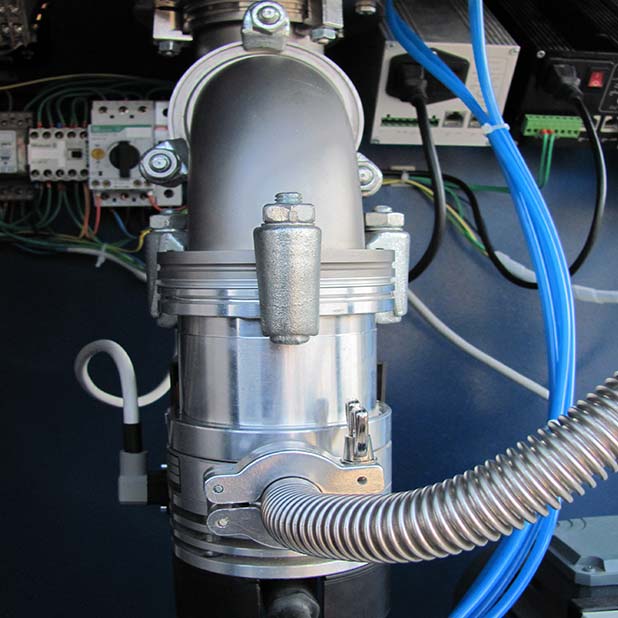

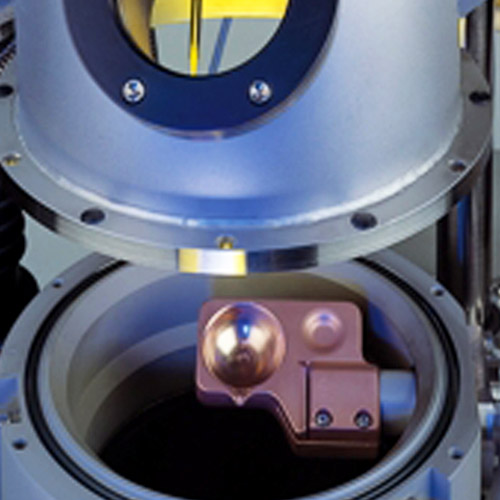

YARAN is a manufacturer of laboratory vacuum arc melting furnaces a sophisticated piece of equipment used for melting and refining materials in scientific and industrial laboratories. In the process of vacuum Arc melting, non-consumable electrodes are used. However, in vacuum arc remelting (VAR), which is generally performed for the purpose of purification and refining, the desired metal itself is melted. YARAN furnace can create the desired vacuum with great accuracy

Features & Options

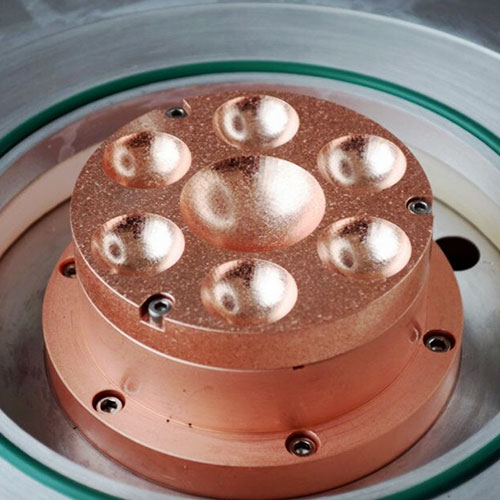

Multi Sample Mold

Rotating and Casting