Chemical Vapor Deposition (CVD)

A meticulous way of creating a protective layer on the material surface

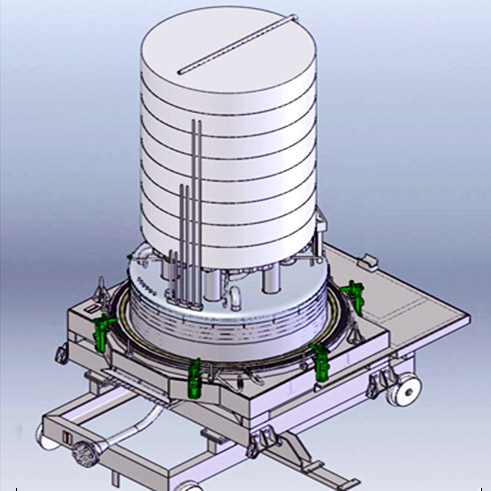

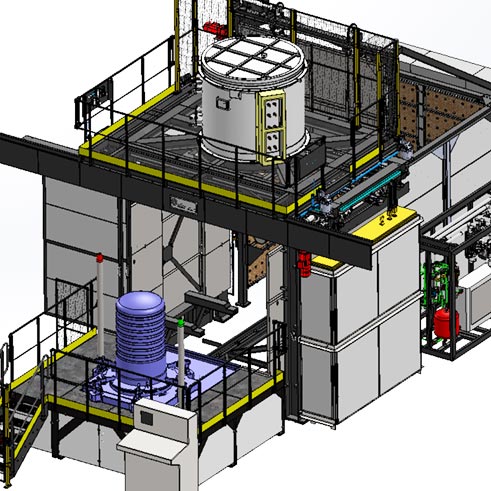

One group of CVD furnaces is industrial furnaces for thermomechanical treatments, forging, and conventional heat treatment. These furnaces are designed to coat the vanes and blades of jet engines using a treatment process called aluminizing, also known as VPA. The advantage of this aluminizing process is the ability to double the production by separating the treatment and cooling cycles of the loads, resulting in an unparalleled ROI. The loads are placed in boxes under an airtight bell in which the aluminizing treatment is carried out under a shielding gas.

another group of these furnaces is dedicated to the semiconductor and photovoltaic industries.

It is currently not possible to supply this product from ECM Group. Please call for more information.